Ingredient Sourcing and Manufacturing

Wilton gel food coloring ingredients – Wilton gel food colorings, known for their vibrant hues and concentrated pigment, rely on a carefully selected blend of ingredients. Understanding their sourcing and the manufacturing process sheds light on the quality and potential environmental impact of this popular product.The primary ingredients in Wilton gel food colorings are a combination of naturally derived and synthetic components. Natural sources might include extracts from fruits, vegetables, and other plant materials, providing certain colors and contributing to flavor.

However, achieving the intense, consistent colors desired often requires synthetic food dyes, which offer superior vibrancy and stability. These synthetic dyes are typically manufactured to meet stringent food safety regulations. The exact composition of each color varies depending on the specific shade.

Ingredient Sourcing

Wilton likely sources its ingredients from various suppliers globally, prioritizing quality and consistency. The selection process emphasizes suppliers who adhere to strict quality standards and sustainable practices. For natural extracts, this might involve sourcing from certified organic farms or regions known for specific crops. For synthetic dyes, the sourcing focuses on manufacturers complying with international food safety regulations and offering high-purity ingredients.

The specific sourcing details are generally considered proprietary information by Wilton.

Manufacturing Process, Wilton gel food coloring ingredients

The manufacturing process involves several key steps. First, the individual ingredients—both natural extracts and synthetic dyes—are carefully measured and combined according to precise formulas for each color. This precise mixing ensures consistent color and intensity across batches. Then, a thickening agent, such as gum arabic or another suitable stabilizer, is added to create the characteristic gel consistency.

The mixture is thoroughly blended to ensure uniformity and then meticulously filtered to remove any impurities or lumps. Finally, the gel is packaged into its distinctive containers, undergoing a final quality check before distribution.

Environmental Impacts

While the environmental impact of Wilton’s manufacturing process isn’t publicly detailed, potential concerns exist. The production of synthetic dyes can involve chemical processes with potential environmental consequences, although modern manufacturing strives to minimize these impacts. Water usage and waste generation are also potential environmental considerations in the manufacturing and packaging stages. Sustainable sourcing of natural ingredients and responsible waste management are crucial factors to minimize the environmental footprint.

So, you’re curious about Wilton gel food coloring ingredients? They’re generally pretty straightforward, but the color intensity sometimes makes you wonder about the components. For instance, the vibrant reds got us thinking – check out this article on does red food coloring cause cancer to ease any concerns. Knowing this, you can confidently choose your Wilton gel colors, understanding a bit more about their composition.

Manufacturing Flowchart

Imagine a flowchart starting with “Raw Material Acquisition” (natural extracts and synthetic dyes). This leads to “Ingredient Preparation and Mixing” where the components are measured and blended according to the color formula. Next is “Thickening Agent Addition and Mixing” to achieve the gel consistency. This flows to “Filtering and Quality Control,” where impurities are removed and quality checks occur.

Finally, “Packaging and Distribution” completes the process. Each stage would have smaller sub-processes, but this overview captures the main steps.

Quality Control Measures

Wilton employs rigorous quality control measures throughout the manufacturing process. This includes regular testing of raw materials to ensure they meet purity and quality standards. Throughout the production process, samples are taken and analyzed to verify color consistency, viscosity, and other key characteristics. Finally, before packaging, each batch undergoes a comprehensive quality check to confirm that it meets Wilton’s strict standards for color intensity, texture, and safety.

This multi-stage approach minimizes the chance of defective products reaching consumers.

Comparison with Other Food Colorings: Wilton Gel Food Coloring Ingredients

Wilton gel food colorings stand out in the world of food coloring, but how do they stack up against their liquid and powdered counterparts? Understanding the differences in ingredients, texture, intensity, and application methods is key to choosing the right coloring for your baking and decorating projects. This comparison will highlight the advantages and disadvantages of each type.Let’s delve into the specifics of what makes each type unique and best suited for certain tasks.

Ingredient Composition and Properties

The core difference lies in the ingredients. Wilton gel food colorings typically use a higher concentration of pigment compared to liquid or powdered options. This results in a thicker, more intense color. Liquid food colorings, on the other hand, are water-based and often contain preservatives and other additives to maintain stability. Powdered food colorings, frequently used in things like candy making, consist of finely ground pigments, often combined with a binder or diluent.

This can lead to variations in the intensity and ease of mixing, depending on the quality and specific formulation of the powder. The gel’s thicker consistency prevents it from significantly altering the texture of batters or frostings, unlike liquid colorings which can sometimes thin the consistency.

Texture and Intensity

- Gel Food Coloring: Thick, concentrated, and delivers intense, vibrant colors. A small amount goes a long way, making it economical. The texture remains largely unaffected when incorporated into recipes.

- Liquid Food Coloring: Thin, watery consistency, less intense color. Often requires more drops to achieve the desired shade. Can alter the texture of some recipes, potentially thinning them.

- Powdered Food Coloring: Varies greatly in texture depending on the brand and formulation. Can be dusty and messy, requiring careful handling. Intensity can also vary; some powders are more potent than others. May require more mixing to achieve even color distribution.

Application Methods and Advantages/Disadvantages

Here’s a summary comparing the application methods and their pros and cons:

| Food Coloring Type | Application Method | Advantages | Disadvantages |

|---|---|---|---|

| Gel | Easy to control, precise application with a toothpick or small offset spatula. | Intense color, doesn’t thin batters/frostings, economical. | Can be difficult to blend completely if not properly incorporated. |

| Liquid | Easy to mix, readily blends into batters and frostings. | Convenient and readily available. | Less intense color, may thin batters/frostings, requires more product for vibrant color. |

| Powder | Requires careful mixing to ensure even distribution; suitable for specific applications like candy making. | Can create very intense color if using a high-quality powder. | Can be messy, intensity varies widely, some may have a slightly gritty texture. |

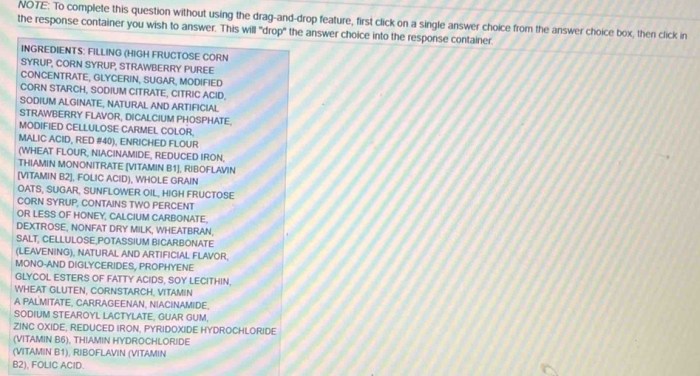

Visual Representation of Ingredients

Understanding the visual characteristics of Wilton gel food coloring ingredients in their raw state and how they transform during manufacturing is crucial to appreciating the final product’s quality and consistency. This section details the visual appearance of the key ingredients before and after processing.The raw ingredients for Wilton gel food coloring primarily consist of sugar, water, and various color additives.

These ingredients undergo significant visual changes throughout the manufacturing process.

Raw Ingredient Appearance

Sugar, in its raw form, typically appears as fine, white crystals. The crystals are small, uniform in size, and possess a slightly grainy texture. They are opaque and reflect light evenly, resulting in a bright white appearance. The consistency is free-flowing, but the individual crystals can be felt. Water, of course, is a clear, colorless liquid with a smooth, even texture and a low viscosity.

The color additives, depending on the desired color of the final food coloring, vary widely in appearance. For example, a red color additive might be a fine, reddish-brown powder, while a blue one could be a dark blue, almost black, granular powder. These powders can have varying textures, ranging from fine and silky to slightly coarse.

Ingredient Transformation During Manufacturing

The manufacturing process significantly alters the visual appearance of the ingredients. The sugar crystals dissolve completely in the water, resulting in a clear, slightly viscous liquid. The color additives are then thoroughly mixed into this sugar-water solution. This mixing process disperses the colorant particles evenly throughout the liquid, resulting in a homogenous mixture with the desired color intensity.

The final product, Wilton gel food coloring, is a thick, gel-like substance. The texture changes from a free-flowing powder and liquid mixture to a viscous, paste-like consistency. The color is intensely saturated, significantly richer than the initial color of the raw color additive powder, due to the concentration and the interaction of light with the gel medium. The overall appearance is smooth and uniform, with no visible particles of sugar or color additive.

For example, a red powder might yield a vibrant, deep red gel, while a dark blue powder would produce a rich, intensely blue gel. The final color and consistency are tightly controlled throughout the manufacturing process to ensure consistent quality.

FAQ Section

Is Wilton gel food coloring vegan?

Most Wilton gel food colorings are vegan, but always check the specific product label to confirm, as formulations can change.

Can I use Wilton gel food coloring in buttercream frosting?

Absolutely! Gel food coloring is fantastic for buttercream, offering intense color without thinning the consistency.

How long does Wilton gel food coloring last?

Unopened, Wilton gel food coloring has a long shelf life. Once opened, store it in a cool, dark place to maintain vibrancy.

Does Wilton gel food coloring stain?

Yes, it can stain, especially darker colors. Always wear gloves and be careful when handling.

Where can I buy Wilton gel food coloring?

Wilton gel food coloring is widely available at craft stores, supermarkets, and online retailers.